Company Profile

TacSense Technology (Shenzhen) Co., Ltd. is a national high-tech enterprise focusing on the full life cycle management of lithium batteries, founded in February 2018, headquartered in Shenzhen, the founding team is formed by high-level talents from home and abroad, such as the University of California, the National University of Singapore, Tsinghua University, the Chinese Academy of Sciences and other high-level talents and industrial engineering teams. The company completed its Series B financing in early 2022, and successive shareholders introduced include Xiaomi Industrial Investment, Lenovo Venture Capital, Chuang Dongfang, and Wang Xiaochuan, founder of Baichuan Intelligence, with a cumulative total of more than 100 million yuan in financing.

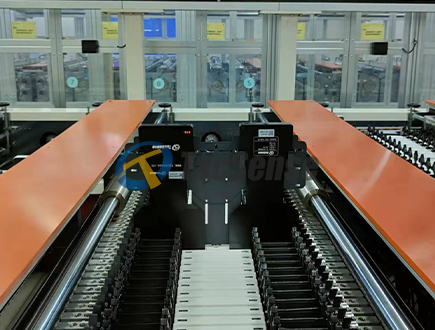

With lithium safety as the goal, the company develops a series of big data failure modeling algorithms based on battery mechanism by taking pressure sensing data as the basis, integrating other multi-dimensional sensing data, and combining with artificial intelligence, digital twin and other technologies to accurately sense lithium aging state, and at the same time establishes a perfect grading early warning system to escort the safety of lithium batteries, and help achieve the goal of dual-carbon.

+

Started in 2018

+

Patent Application 100 +

%

Average R & D spending over 45%

+

Help 300 enterprise intelligence

Partners

News dynamics

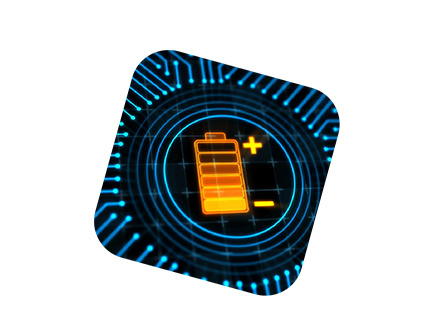

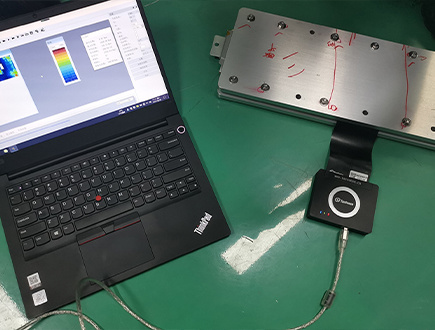

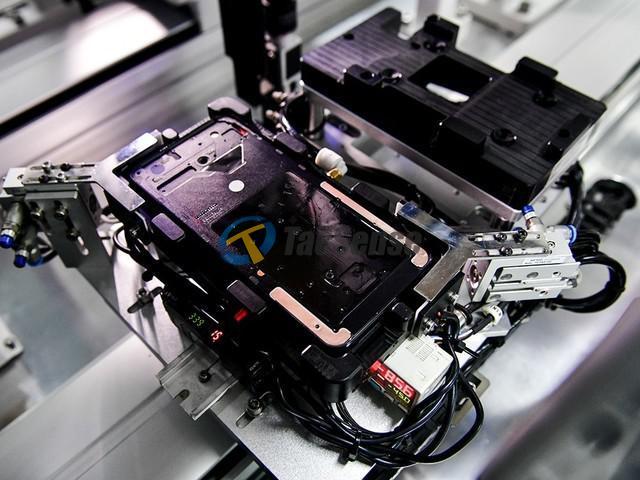

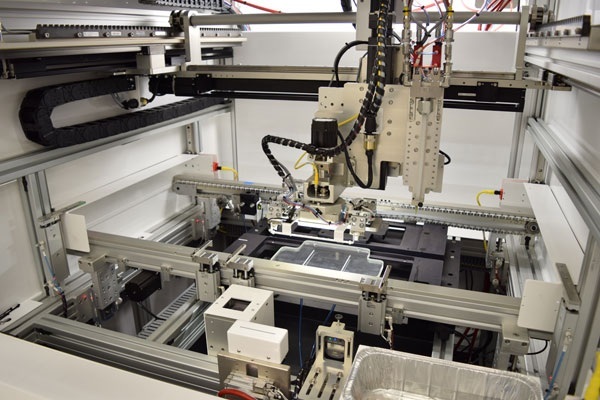

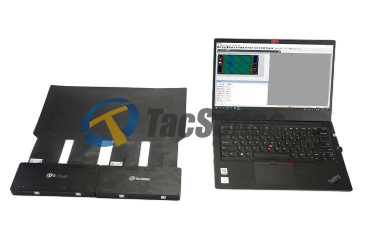

Pressure distribution measurement system and new energy lithium battery pressure distribution detection

Industrial pressure testing consulting

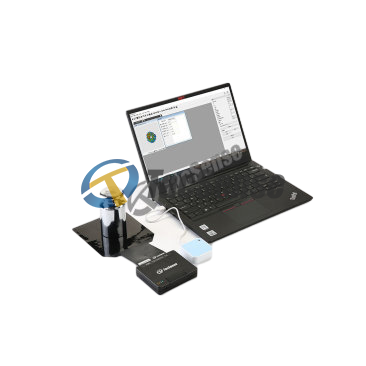

TWS Headphone Pressure Sense Solution and Consumer Electronics

Internet of Things Pressure Sense Scheme Consultation

Administrative and other advice