- Home

- Core technology

- Solution

-

Product

Pressure distribution measurement system

Wireless pressure distribution measurement system

Multi machine collaborative pressure distribution measurement system

Multi-channel pressure distribution measurement system

TWS headphone pressure sensing module TS2223

Electric toothbrush pressure sensing module

Thin film distributed pressure sensor

BLM Battery Full Life Cycle Monitoring and Management Platform

- About TacSense

- Contact us

- EN

Contact Us Contact Us

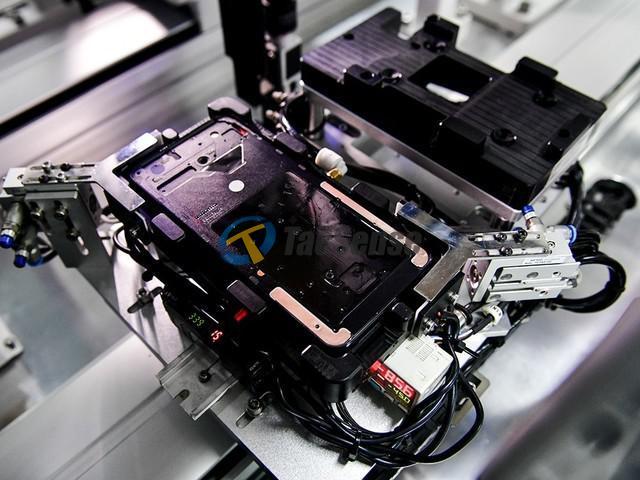

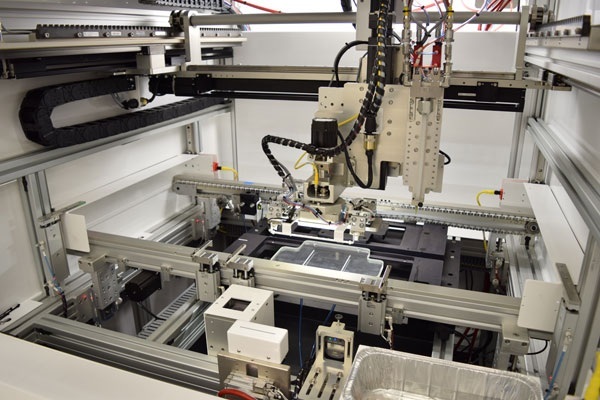

Industrial applications: equipment for testing the expansion force of battery cells, testing the capacitance of battery cells, testing the pressure bonding and flatness of industrial machines.

Contact: Mr. Chen 18026916463

Consumer electronics applications: TWS,OWS, Switch replacement application.

Contacts: CLT 13823378048

Lithium battery lifecycle system: 0755-86535421

©COPYRIGHT 2023 TacSense Technology (Shenzhen) Co., Ltd. ALL RIGHTS RESERVEDGuangdong ICP No. 20062627Website construction:China Enterprise Power Shenzhen SEO

-

-

-

Online consultation

Service Time:8:00-20:00

Business negotiation:

Industrial and new energy pressure distribution measurement equipment:Mr. Chen 18026916463

Application in various industries of consumer electronics:Mr. Chen 13823378048

Lithium battery lifecycle system:0755-86535421

-

-

-

©COPYRIGHT 2023 TacSense Technology (Shenzhen) Co., Ltd.

Website construction:China Enterprise Power Shenzhen SEO