Thin film distributed pressure sensor

Ultra thin and flexible: seamlessly integrated without changing the structure of the battery module; Pressure distribution detection: presenting the expansion force distribution state in a pressure cloud map with high accuracy, sensitivity, and linearity; Wide temperature range: can meet continuous pressure monitoring in high temperature environments with thermal runaway; High reliability and ultra long service life:>15 years of service life; Cascade design saves space and facilitates module PACK integration

- Description

-

Thin-film distributed pressure sensors

Thin-film distributed pressure sensors

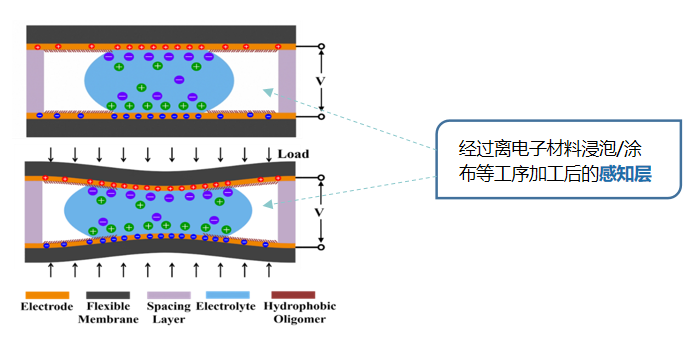

Introduction to electronic sensing technology

In 2010, the team of Professor Pan Tingrui, the chief scientist of the company, first proposed the fourth-generation sensing mechanism - interface ionic tactile sensing technology different from the existing resistive, capacitive and piezoelectric sensing, and the ionic sensor adopts a new pressure sensing principle to sense the external pressure through the change of the contact area of the deformable ionic material layer and the surface of the flexible conductive material

In addition to the leading technical parameters, ionic sensing can provide real-time, high-quality, low-noise tactile signals, and can have the characteristics of full flexibility, optical transparency and ultra-thin packaging. Its characteristics of "flexible, soft, transparent, dense and wide" make the products have unique competitive advantages in consumer electronics, industry, medical and other fields

Technical advantages and characteristics of TacSense products

Technical advantages and characteristics of TacSense products

· Based on the principle of true pressure detection, it has high linearity

· The high linearity combined with the self-calibration algorithm eliminates the need for calibration of assembled products

· Wide pressure detection range, which can meet the needs of ultra-high expansion force detection of solid-state cells.

· Wide temperature application range, which can meet the needs of real-time monitoring of cell thermal runaway

· The signal-to-noise ratio can reach 4,000:1, which is an order of magnitude improvement over traditional pressure-sensitive technologies

· High-quality, low-noise signals liberate dependence on ICs/high-precision ADCs

· Thanks to the simple design and exclusive material advantages, the sensor can be fabricated in a cost-effective and fast way, reducing the cost by up to 90% compared to the competition · The sensitivity is up to 1.58μF/kPa and up to 0.025% of the range, which highly mimics the human tactile characteristics and indicators

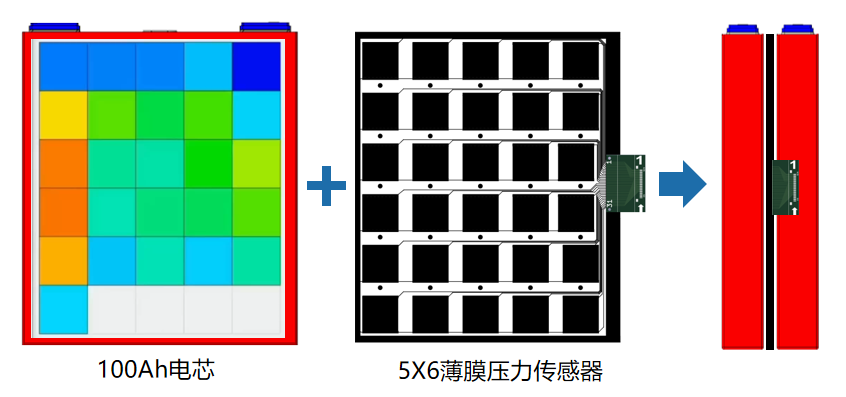

· With a thickness as low as 0.1mm and a space density of less than 1mm2, it can realize customized matrix sensors and seamless integration with cell modules

Sensor specifications

Nonlinearity

<3%

repeatability

<5%

precision

<5%

Operating temperature

-20℃—200℃

Operating humidity

0-85%

thickness

<0.15mm

Pressure range

500KPa

Pressure points

30 (5X6)

Sensing point spacing

9.2mm

Service life

> 15 years

· Ultra-thin and flexible: direct and seamless integration

without changing the structure of the cell modulePressure distribution detection: Present the expansion force distribution state in the form of pressure contour diagram with high precision, high sensitivity and high linearity

Wide temperature range: It can meet the continuous pressure monitoring

in the high temperature environment of thermal runawayHigh reliability, ultra-long life: > 15 years service life

Cascade design, space-saving, easy to integrate module PACK Schematic diagram of sensor assembly

Schematic diagram of sensor assembly

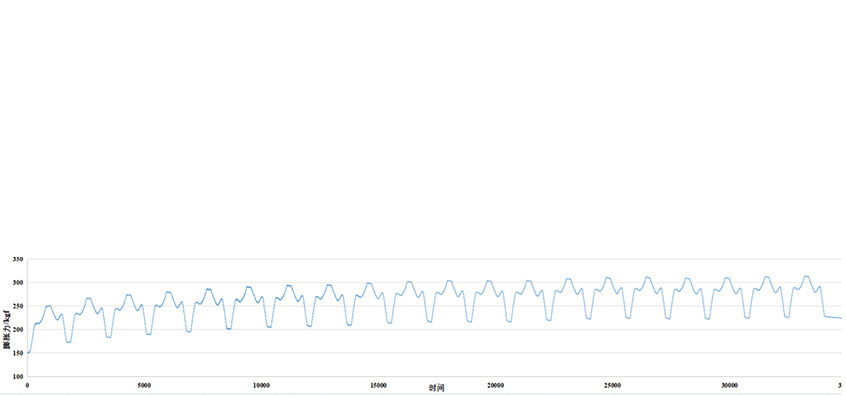

20-turn cycle charge/discharge pressure curve

Related Products

Get the latest product information