new energy

TacSense Technology Assists Battery Thermal Loss Research | Application of Tactile Sensing Technology in Lithium ion Battery Thermal Loss Warning

Release time:

2024-05-29 14:49

Author information and article abstract

Focusing on energy storage technology to assist in energy storage safety. Recently, TacSense Technology (Shenzhen) Co., Ltd., in collaboration with the Tianjin Fire Department of the Emergency Management Department and the Zhongguancun Energy Storage Industry Technology Alliance, published an article titled "Application of Tactile Sensing Technology in Thermal Loss Warning of Lithium ion Batteries" in the Journal of Fire Science Academy and Technology. The article focuses on the application of tactile sensing technology - distributed thin film pressure sensing system for thermal runaway safety monitoring of lithium-ion batteries for energy storage. A 52 Ah square shell lithium iron phosphate battery was selected as the research object, and the thermal runaway process of single and module batteries was triggered by a heating plate. Combined with various real-time monitoring methods such as force, electricity, and heat, the thermal runaway process at the single and module levels was analyzed in detail. The experimental results have shown that, relative to the characteristics of battery temperature and voltage, the battery expansion force can provide 8.9 minutes and 6.0 minutes early warning of thermal runaway at the cell and module levels, respectively. Introducing force dimension data monitoring can effectively improve the warning ability of thermal runaway in lithium-ion batteries for energy storage.

Experimental plan

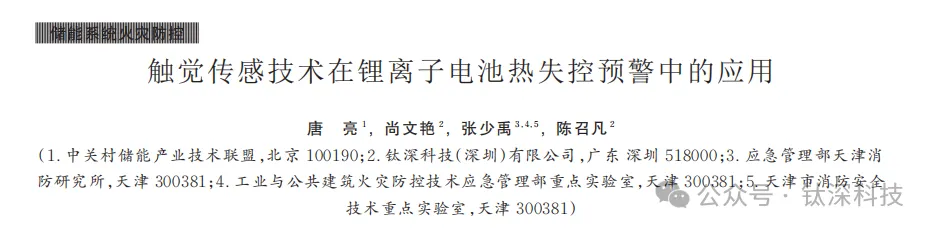

1. Single cell battery testing test layout

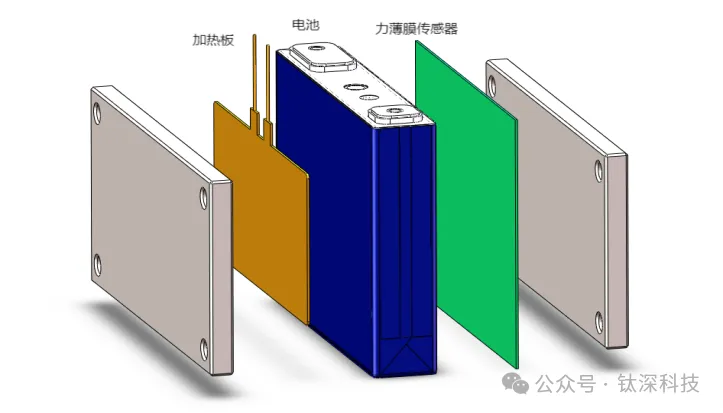

2. Module level testing test layout

Results and Discussion

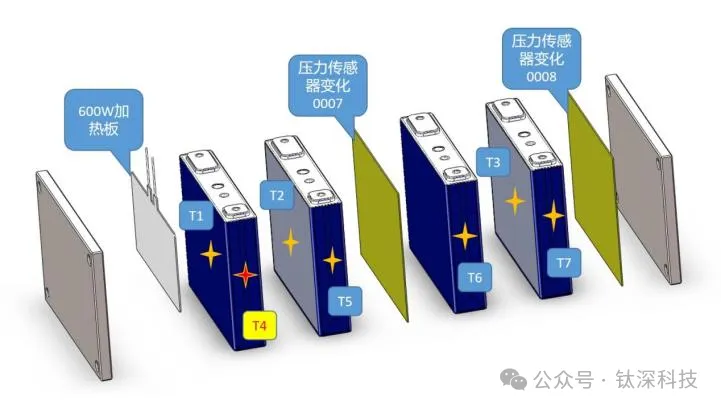

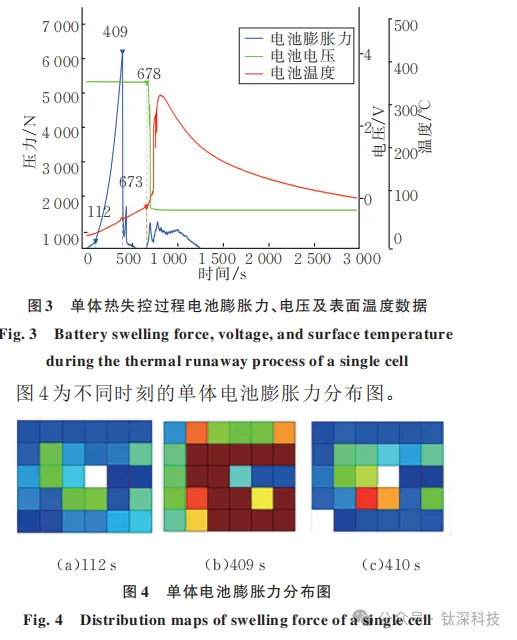

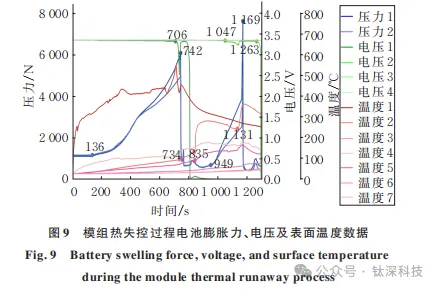

The author first conducted a thermal runaway test on a single cell battery, and the results showed that the battery expansion force rapidly increased at 112s, while a sharp increase in temperature occurred at 673s and a rapid drop in voltage occurred at 678s. Compared with temperature, voltage, and expansion force data, due to the fact that the battery itself is a closed space and heat and stress are prone to local accumulation, expansion force shows a 9.35 minute lead in identifying thermal runaway, and has great potential in energy storage safety warning. Meanwhile, the author further explored the main concentration points of pressure during the thermal runaway process through the cloud map changes of distributed thin film pressure sensors in 5 rows and 6 columns. The results show that during the thermal runaway process, the increase in expansion force is mainly concentrated in rows 2-5 and columns 2-6, and this positional relationship is basically consistent with the rapidly decreasing force area shown in the cloud map after opening the valve for pressure relief.

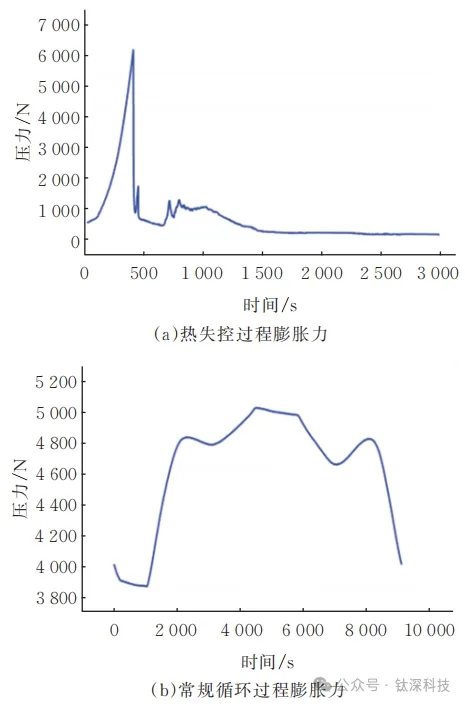

To clearly determine the advance amount of expansion force as a warning signal, the author compared the growth rate of battery expansion force under two different states of conventional 1C cycle and thermal runaway for the same battery cell. The results show that during the conventional cycle, the absolute value of the expansion force change rate of the battery cell is between 0 and 0.8 KPa/s. However, if the expansion force change rate of 8 KPa/s (i.e. 10 times the maximum expansion force growth rate during the conventional cycle of the battery) is selected as the warning threshold for thermal runaway, the expansion force warning signal will start warning at the 136th second. Compared with the abnormal voltage signal (678S) of the battery, the abnormal temperature signal (673S) is advanced by 9.0 and 8.9 minutes, respectively.

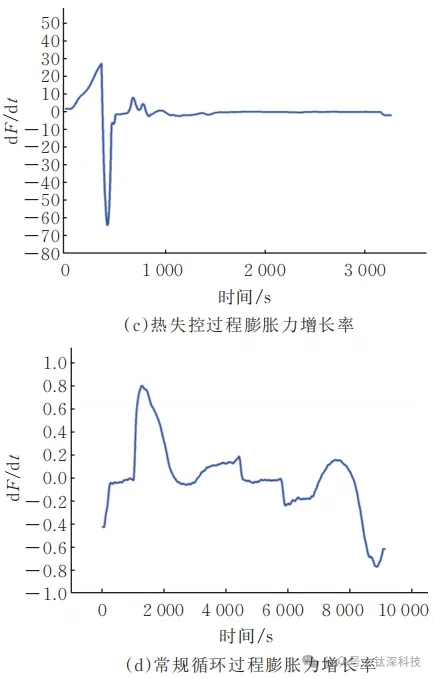

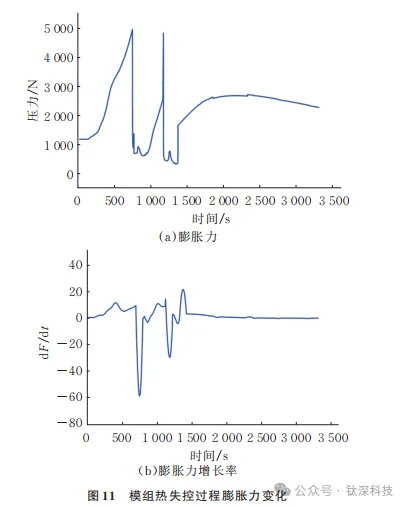

Unlike the hierarchical structure of battery cells, thermal runaway in battery systems often occurs and is accompanied by spread after triggering and experiencing thermal runaway. Therefore, the author simulated a battery system for module level thermal runaway testing. The test results showed that two sensors placed at different positions on the module had a rapid increase in signal from the 136th second, until the 742nd second (when thermal imaging and video display showed the spray valve) reached its maximum value and then rapidly decreased. The sensitivity of battery anomalies to expansion force, voltage, and temperature shows a lag. It is not until 706s that the voltage of battery 1 begins to rapidly drop, and at 734s, the temperature rise of T2 begins to increase abnormally. The recognition of thermal runaway by expansion force is advanced by 9.5 minutes. In addition, during the occurrence of thermal spread, the expansion force shows a rapid secondary increase, which is earlier than the voltage and temperature parameters. This indicates that the expansion force still has a significant potential warning ability for secondary thermal runaway caused by thermal spread.

Finally, consistent with the logic of individual level warning, the author selected an expansion force growth rate of 8KPa/s (i.e., 10 times the expansion force growth rate during conventional cycles) as the warning threshold. The safety warning will be triggered by the expansion force warning signal at the 348th second, and compared with the earliest abnormal signal time in temperature and voltage signals (706s) by 6.0 minutes in advance, sufficient time has been reserved for early monitoring and warning of thermal runaway, as well as for the initiation of safety systems and the implementation of safety measures corresponding to safety accidents.

Summary

The author innovatively introduces a new tactile sensing technology - thin film pressure sensing system, which can monitor the expansion force during thermal runaway in real-time. The experiment compared the differences in the changes of battery expansion force signal, temperature signal, and voltage signal during the thermal runaway process of lithium batteries, and the results showed that:

1) The battery will experience significant expansion before the complete thermal runaway process, and the expansion force signal can identify thermal runaway anomalies very early before the battery valve bursts;

2) When selecting 10 times the expansion force growth rate during the regular cycle of the battery as the warning threshold, it shows an advance of 8.9 minutes compared to the temperature/voltage signal in the monomer, and a advance of 6.0 minutes at the module level. Moreover, in the secondary thermal runaway stage at the module level, the rapid response of expansion force growth is in sharp contrast to the lag of temperature and voltage changes at this time.

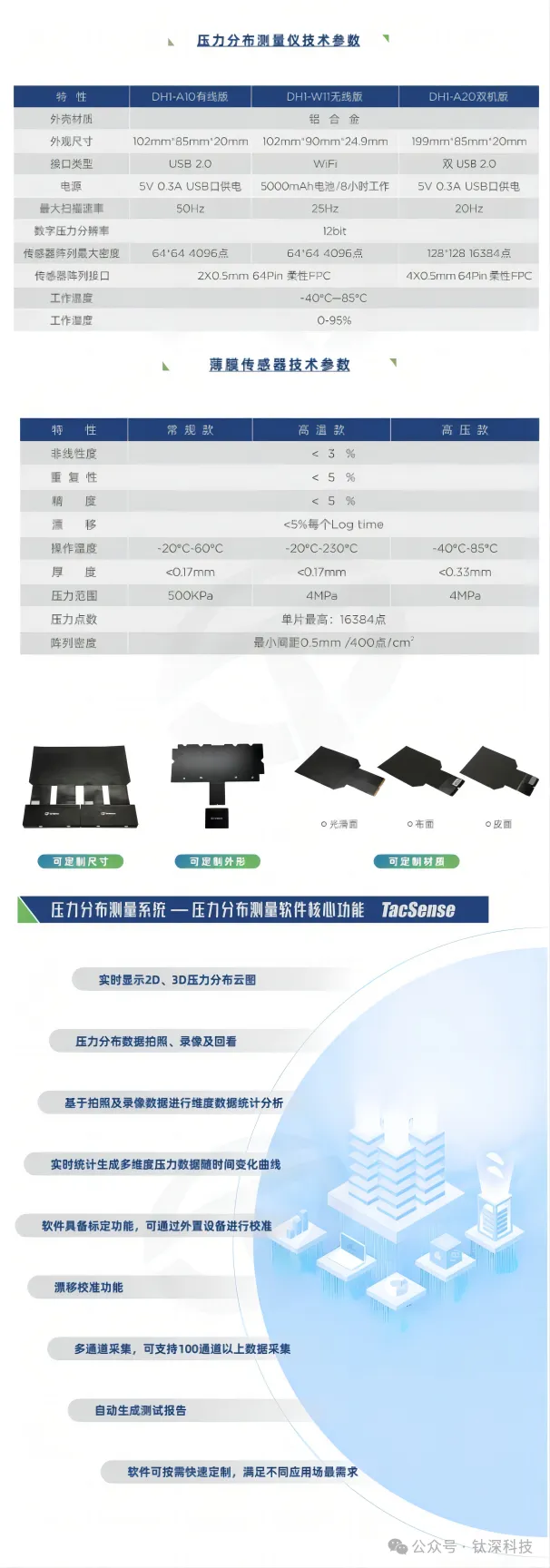

Pressure distribution measurement system

The pressure distribution measurement system uses ultra-thin and flexible thin film sensors to accurately measure the contact pressure distribution of the contact surface. It can display the contact pressure of the entire contact surface in a two-dimensional or three-dimensional color pressure distribution image and record the entire force process.

The pressure data detected in real-time can be subjected to relevant statistical analysis, and can be exported for secondary data analysis or development.

At present, pressure distribution measurement systems have been widely used in various application scenarios such as pressure detection throughout the entire chain of new energy lithium batteries and industrial automation detection, empowering various links in the industrial chain.

recommend News