new energy

The Past and Present of Flexible Pressure Sensing Technology

Release time:

2023-11-16 10:13

The Past and Present of Flexible Pressure Sensing Technology

- ionized sensing technology, from droplet sensors to artificial skins

Through the response of artificial skin to external stimuli, flexible tactile sensing technology has developed rapidly over the past decade. Among them, flexible pressure sensing, as the most important part of tactile sensing, has been widely studied and has been applied in the fields of industrial, medical and consumer electronics. Traditionally, flexible pressure sensing has been based on optical and electrical mechanisms, with the latter gaining wider attention due to its higher device flexibility, ease of integration, and simple structure. Iontronic is a new sensing mechanism developed in recent years, which records the pressure value by measuring the supercapacitance value of the ionic-electron electric double layer that changes under pressure. Compared with other sensing mechanisms such as piezoresistive, piezocapacitance, piezoelectric and triboelectric, ionized sensing is considered to have extremely high pressure response sensitivity, signal-to-noise ratio, anti-interference, pressure resolution, etc., in addition to unique characteristics such as high transparency and wide dynamic and static force response.

Previously, the so-called flexible sensors on the market were only compared to MEMS pressure sensors, and they were not really flexible pressure sensors. The invention of ionized sensing technology represents the birth of true flexible sensing technology. This year is the 10th year of the first ionized ionized tactile sensing technology in the world, and it is also the 10th anniversary of the birth of the fourth true flexible, true tactile, ultra-thin and highly sensitive ionized pressure sensing technology after piezoresistive, capacitive and strain gauge types.

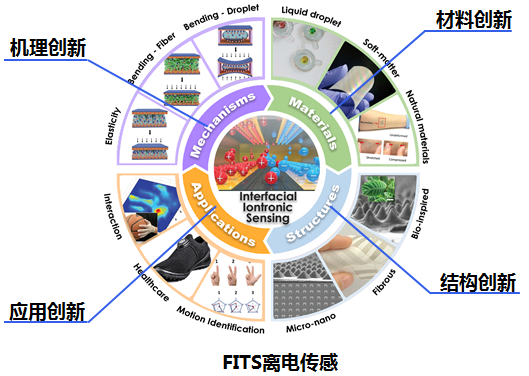

Recently, Professor Tingrui Pan of the Department of Biomedical Engineering at the University of California, Davis, the inventor of ionized tactile sensing technology, and Chang Yu, associate researcher of the Shenzhen Institute of Advanced Technology, Chinese Academy of Sciences, Dr. Liu Wang and Associate Professor Chuanfei Guo from Southern University of Science and Technology published in Advanced Materials, a top international materials journal".First Decade of Iontronic Sensing: From Droplet Sensors to Flexible Electronics". This paper summarizes the development of ionized tactile sensing technology, and makes an in-depth analysis and introduction of ionization mechanism from four aspects: pressure response mechanism, ionized functional materials, pressure-responsive structure and application of ionization technology, and puts forward the future development prospect and direction of ionization technology.

What is ionized tactile sensing technology? What's new in this technology? What product innovations will be triggered? What industries will be promoted? Today, we will unveil the mystery of ionized pressure sensing technology.

1

Discover ionized technology -- technological innovation triggered by a drop of water

Fig.1 Four aspects of ionized sensing mechanism: pressure response mechanism, ionized functional materials, pressure-response structure and technical application, and their main classifications

2

The future is here -- ionized haptic sensing technology leads product and application innovation

To sum up, ionized sensing has technical advantages that other tactile and pressure sensing technologies cannot match due to its own technical principles. The flexible characteristics of ionized sensing technology can subversively change the rigid physical form of traditional information devices and systems, and realize the efficient integration of information with people, objects and the environment. Realize the flexibility of information acquisition, processing, transmission, display and energy, and better realize the interconnection of all things. The ionization sensing technology has the characteristics of true flexibility, ultra-thinness, high light transmittance, high signal-to-noise ratio, and high anti-interference in the environment. Due to its unique and natural technical characteristics, the ionized sensing principle has quickly occupied a place in the field of flexible pressure sensing, and has led product innovation in application fields such as environmental interaction, health monitoring, and action recognition. For example, ionized flexible sensors can be attached to fully flexible fabrics, have ultra-low power consumption, and support a variety of wearing styles (shoes, wrists, socks), so they can be used for continuous monitoring of pulse waves, heart rate, respiration, and blood pressure trends, so they can be used to monitor the human body 7/24; Wearable gloves based on ionized sensing fabrics can accurately obtain the pressure distribution of gripping actions; The flexible sensor integrated into the tongue can directly measure the number of steps, cadence and other exercise data, pulse waves, respiratory waves and other physiological data, and estimate blood pressure, cardiovascular health, etc. through algorithms. The helmet equipped with a flexible sensor can not only detect the actual wearing of the helmet, but also monitor the wearer's vital signs in real time, especially in special industries such as official business or mines, to ensure the safe operation of staff; The multi-point sensor array based on skin ionic functional materials can measure the muscle movements brought by different gestures, so as to complete the recognition of sign language. Technological innovation has led to the diversification of products and applications, and solved the pain points of more industry applications, thereby contributing to the rapid development of the industry.

3

Always on the road -- Ionized sensing technology empowers tactile sensing technology and helps the rapid development of the industry

With the gradual enhancement of the multi-dimensional perception demand of various industries, the tactile sense related to people must overcome the bottlenecks encountered in flexibility/noise/sensitivity, and the ionized sensing technology truly empowers the tactile perception technology and promotes the breakthrough and rapid development of industry, health, consumer electronics and other industries.

In the medical and health industry, for example, the sense of touch is the precise way to accurately know the vital signs of the human body. The ionized flexible sensor greatly improves the pulse diagnosis accuracy of the pulse diagnostic instrument, so that the wisdom of traditional Chinese medicine can benefit the people. Ionized flexible sensors can also be used in health examination equipment, such as smart trails, to detect the gait and solar pressure distribution of walkers, and to know suspected neurodegenerative diseases or post-illness rehabilitation, so as to make the health and rehabilitation evaluation of the health insurance industry more objective. At present, medical robots or medical devices do not have the ability of tactile detection and haptic feedback, which puts forward higher requirements for the detection of many diseases and the control of medical devices. The ionized haptic sensing array can endow all kinds of medical devices with tactile perception capabilities, so that they can more accurately analyze tissues and lesions in the human body and better achieve collaboration with doctors, and have a wide range of clinical application scenarios.

The ionized flexible sensor can make the surface of any material feel tactile controllable, and its array sensing layout can provide a more natural input method, so it can be widely used in simple weighing, gesture input and other solutions, so that the interface between people and things, and objects and objects have a sense of touch.

In the manufacturing and manufacturing industries, for example, it is important to ensure accurate pressure values. Because accurate pressure values not only increase the life of the equipment, but also improve the production yield and improve the safety of the production line operation. Therefore, the acquisition of pressure values and pressure distribution data is a key factor in optimizing and improving industrial efficiency. However, conventional pressure-sensitive paper is not only expensive, but also can only give qualitative results, i.e., uniform or uneven pressure distribution. A series of problems such as the inability to carry out quantitative analysis, the inability to rely on imports, the inability to independently intellectual property rights, the high price and the inability to guarantee full inspection, have led to the inability of traditional pressure testing methods to meet the requirements of the rapid development of China's production and manufacturing industry. The pressure distribution measurement system based on ionized sensing technology can not only comprehensively understand the magnitude and distribution of force, but also record the dynamic trajectory of force change in real time. Therefore, the application of ionization technology can realize real-time monitoring of the industrial manufacturing process, reduce the cost of quality inspection, improve the coverage and efficiency of quality inspection, improve the industrial yield of manufacturing, and improve the safety of production line operation. Ionized technology can also be integrated into industrial equipment such as manufacturing, enabling intelligent industrial equipment.

From the perspective of the technology itself, high signal-to-noise ratio ionization sensing signal processing, ionization sensing temperature and humidity stability research, and implantable ionization sensing device research and development will also be the future development points of ionization sensing technology. The continuous improvement and improvement of technology will enhance the competitiveness of ionization technology itself, and ultimately benefit and help the development of the industry and product innovation.

Note: To reprint this article or quote its content, please contact TacSense Technology. Illegal reproduction or quotation of laws and regulations must be investigated.

recommend News